Air Silk®

A revolutionary new fiber product—out of thin air

Mass production processes commonly seen in apparel manufacturing consume enormous amounts of resources and energy and emit high quantities of carbon dioxide. Decarbonizing the garment industry—which is plagued with numerous environmental issues—requires refraining from using limited virgin resources and instead seeking new options for raw materials, hence a recent focus on reuse and recycling. The need for decarbonization is particularly prevalent in the enormous global luxury apparel market.

Made from proteins created by marine purple photosynthetic bacteria, Air Silk® represents an entirely new raw material solution. This groundbreaking fiber is biodegradable both in soil and marine environments. Free from reliance on fossil resources, Air Silk® can be produced with zero carbon emissions using the inexhaustible resources of carbon dioxide and nitrogen.

Synthetic silk with the same fiber structure as spider silk

To create Air Silk®, we first attempted to introduce a gene which produces protein-based fibers in spiders into marine purple photosynthetic bacteria. Spider silk has attracted attention in recent years as a natural fiber with lightness and toughness comparable to steel. Led by Keiji Numata, founder and CTO of Symbiobe, this initiative made use of the Spider Silkome Database—the world's first comprehensive database on the physical properties and protein structure of spider silk taken from over 1,000 species—as a design reference for new DNA sequences.

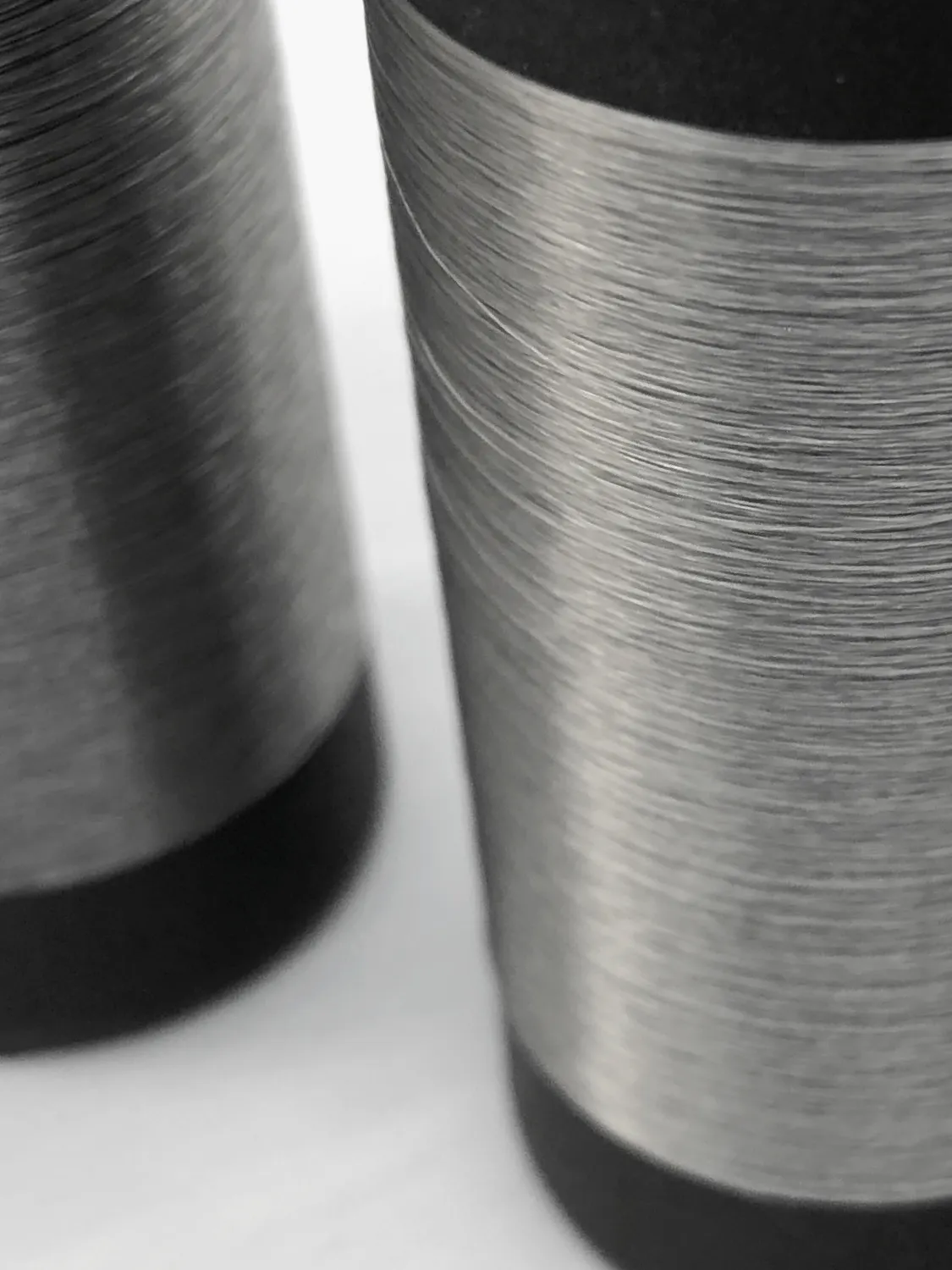

Mass cultivation of our genetically modified marine purple photosynthetic bacteria takes place in seawater conditions, where the bacteria are exposed to light suitable for the photosynthesis that causes them to fix carbon dioxide and nitrogen. The metabolized proteins are extracted, refined, and spun into Air Silk®, which has the same fiber structure as spider silk and boasts a silky sheen and smoothness.

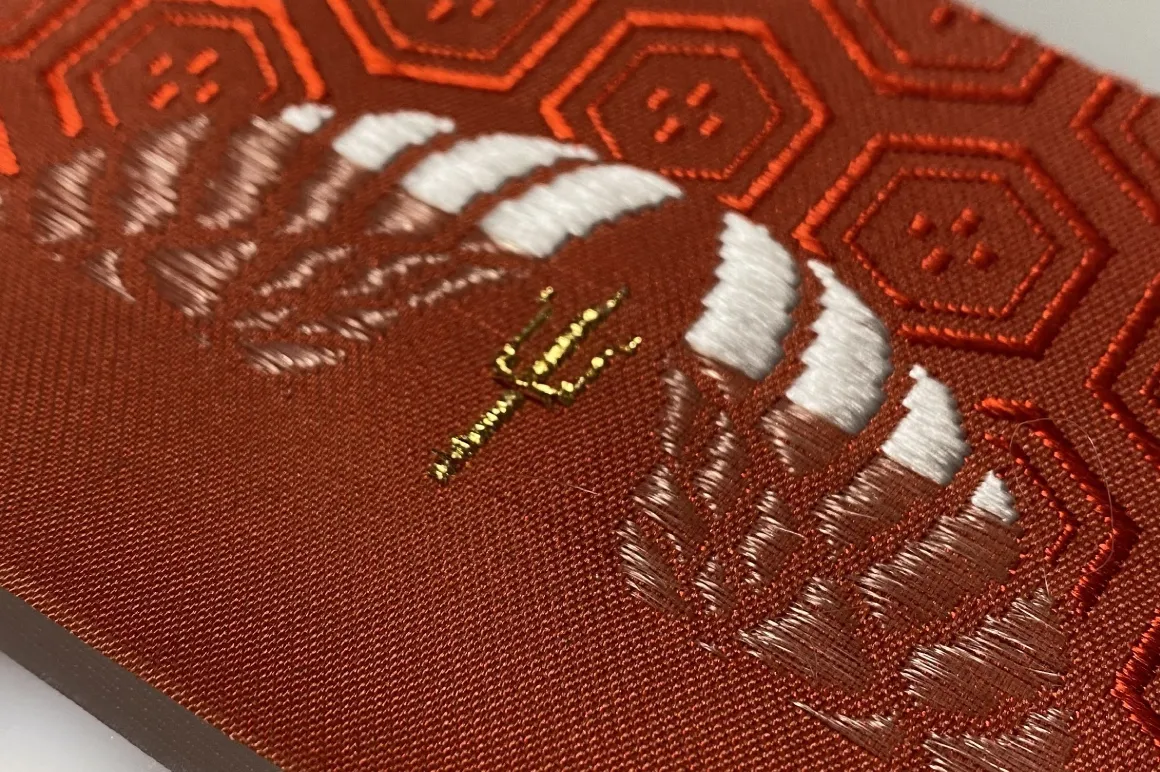

In order to promote commercialization of this new product, we recently produced our first-ever Air Silk® prototype by weaving these novel fibers into a piece of Kyoto’s traditional nishijin-ori silk fabric. This project served to demonstrate the feasibility of using Symbiobe’s technology to create and commercialize textile resources from the air.